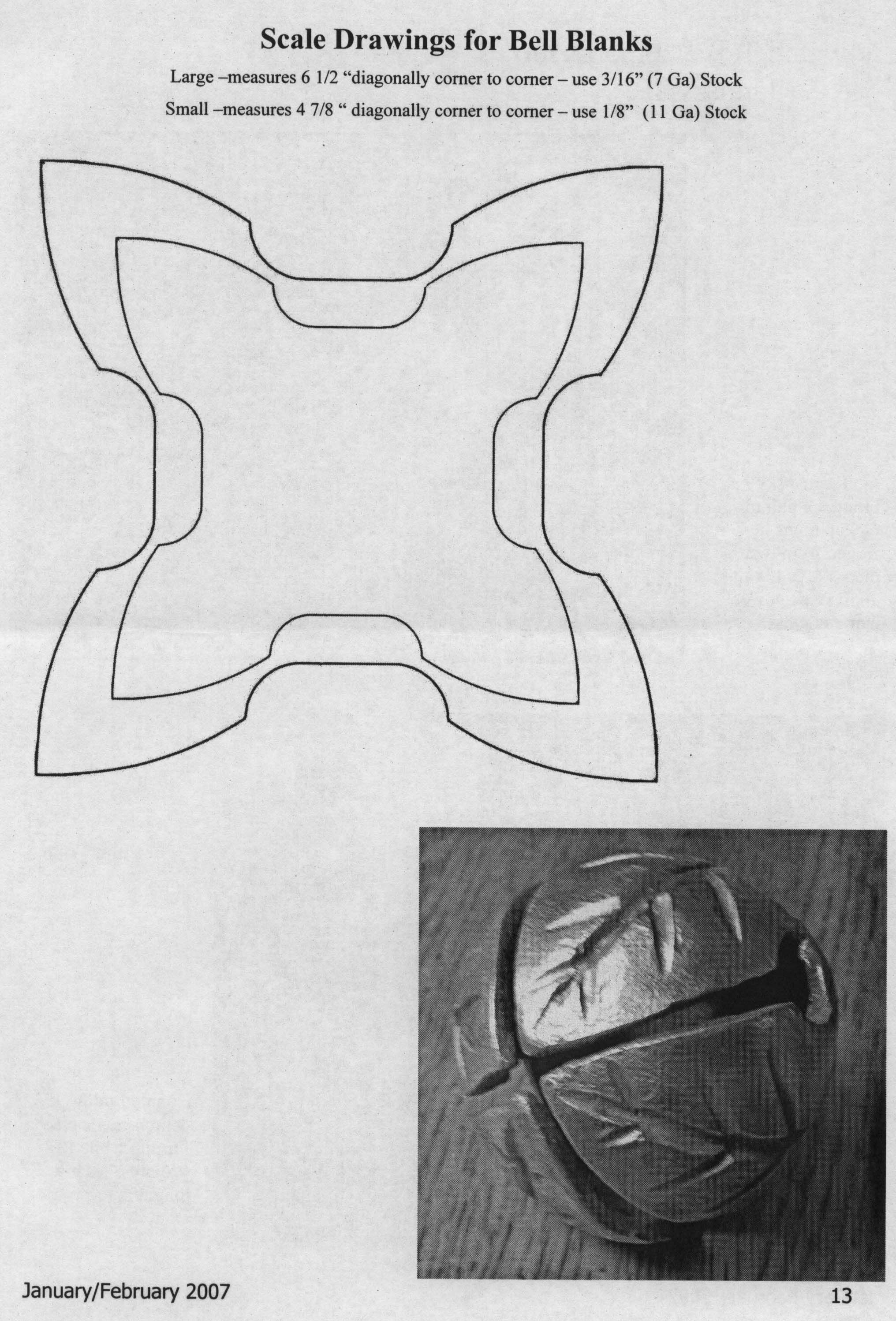

Welding Gas Regulator

Welding gas regulator

Argon Regulators normally show Gas Flow Rate in Litres Per Minute and Cubic Feet Per Hour. It's important to make sure the Delivery Gauge reads Flow Rate as most Mig and Tig Welders will quote a recommended delivery in Litres per Minute. An Argon Regulator should also be used for Argon/Co2 Mixed gases.

What is a gas regulator in welding?

A welding regulator is a device that reduces high-pressure gas from a cylinder to the appropriate delivery pressure to meet the welding application requirements. The regulator does this by reducing the flow of the gas, which allows gas to be used effectively and minimizes safety hazards.

What should welding gas regulator be set at?

A good starting point is 20 to 25 CFH. Keep an eye on the weld surface and the area around weld toes. If you notice porosity, increase the flow.

Can you use a Co2 regulator for Argon?

APPLICATIONS - The gas pressure regulator can be used with argon, CO2 and helium.

What is the correct gas pressure for MIG welding?

Ensure you read the PSI (Pounds per Square Inch) on the regulator gauge on your left. The ideal gas pressure range for MIG welding should be three to eight PSI.

What is the proper gas setting for MIG welding?

MIG welding requires DC electrode positive, or reverse polarity. The polarity connections are usually found on the inside of the machine. Set gas flow. Turn on the shielding gas and set the flow rate to 20 to 25 cubic feet per hour.

How many types of gas welding regulators are there?

Following are the 5 different types of gas welding: Oxy-acetylene gas welding. Oxy-gasoline gas welding. MAPP gas welding.

How do you prevent backfire in welding?

There are several things you can do to help prevent flashbacks, fires and explosions:

- If using acetylene, keep the pressure below 15 pounds.

- Purge your hoses before lighting the torch.

- Never light your torch with a mixture of fuel and oxygen.

- Check valves should be installed on both torch inlets and operating properly.

Which gas regulator is best?

Top 5 Best LPG Gas Cylinder Regulators in India

- #top 1. SKYGOLD Gas Regulator Red Regulator. Created with Fabric.js 1.7.22 9.8.

- #top 2. DE Lpg Gas Regulator Red Regulator. Created with Fabric.js 1.7.22 9.5. ...

- #top 3. LPG Gas Regulator Red Regulator. Created with Fabric.js 1.7.22 9.3. ...

- #top 4. GSS Automatic Cut Off On Flame Gas Safe…

Can you have too much gas when MIG welding?

Operating with an excessive gas flow rate can cause turbulence to occur at the base of the welding gas nozzle. Turbulence means air gets sucked into the flow of welding gas. This can result in the appearance of porosity, inclusions, and spatter – all the issues that welding gas is meant to prevent in the first place!

How do you adjust a welding regulator?

If your setting gas flow on a Mig or Tig, operate the machine so it's gas valve is open. Slowly turn the Gas Regulator Control Knob clockwise. When you start to feel resistance the gas should start to flow and the Delivery Gauge Needle will start to move around the scale.

How many CFM do I need for MIG welding?

Comments for correct cfm for mig welding if using 3/8 inch nozzle minimum cfm is 15 with 18-22 cfm is in normal range 30 cfm being the maximum setting. if using 1/2 inch nozzle 18 cfm is minimum 22-27 cfm being in normal range and 40 is maximum cfm.

Can you use a Argon CO2 regulator for TIG welding?

About this item. Argon/CO2 Regulator For Welding:Argon Regulator is a ideal choice for professional TIG/MIG welding applications, which can be used to reduce and control pressure levels.

Are argon and CO2 tanks the same?

Argon tanks (which store highly pressurized gas) need to be able to withstand a much higher pressure than CO2 tanks (which store mostly liquid CO2 in a similar way to an LP tank, but at a much higher pressure than LP), and any argon mix, is also a pressurized gas.

Can you use nitrogen regulator for Argon?

A nitrogren regulator used for Nitrogen and Argon - it will fit both tanks. A nitrogen regulator has a higher high-pressure gauge than a CO2 regulator. (The starting pressure in a Nitrogen/Argon tank will be about 2200 p.s.i. as opposed to 800 p.s.i for a CO2 tank.)

Can you MIG weld steel with 100 argon?

In summary, it is possible to stick steel together using a good MIG welder with 100% Argon shielding gas. But, you end up with a shoddy-looking, weak, brittle weld. If you need a strong, quality weld, 100% Argon is NOT a good choice for MIG welding steel.

What pressure should shielding gas be?

MIG shielding gas flow is set and measured as cubic feet of gas per hour (CFH) NOT pressure in psi. Unlike oxyfuel welding and cutting, MIG gas flow rates are very low. The gas pressure in the hose going into a wire feeder/welder, while welding, typically varies from 3 to 8 psi.

How many psi is a full argon tank?

But when an Argon of Argon/CO2 tank is full, it should read near the maximum pressure (which is 2015 psi most times). As you use gas, the pressure will drop accordingly. Some examples, as you use gas to weld, you will have ¾ of a tank left when the pressure reads about 1500 psi. At ½ full, it will read around 1000 psi.

Do you push or pull when MIG welding?

Push or pull: Here the rule is simple. “If it produces slag, you drag,” says Leisner. In other words, you drag the rod or wire when welding with a stick or flux-core wire welder. Otherwise, you push the wire with metal inert gas (MIG) welding.

What is the best gas mix for MIG welding?

MIG Gases. If you're going to be MIG welding, there are two main gases that are used: pure argon and an argon/carbon dioxide mix. The most common (and recommended) Ar/CO2 mix is a 75/25 ratio, with 75% of it being argon and 25% of it being CO2.

Post a Comment for "Welding Gas Regulator"